Control Zero H7 OEM - M10059

3D View

Description

The Control Zero series of flight controllers represents 3DR's commitment to continuous improvement. Our goal with this series was to take every lesson learned from our +10 years of flight controller design and make the best pro-consumer and commercial flight controller on the market. Our journey begins with this Zero in its OEM form factor - this is a no-compromise triple IMU commercial-grade flight controller.

Purchase Auto Pilot Purchase Case

Specifications

| Specifications | Control Zero H7OEM |

|---|---|

| Main Processor | 32-bit STM32H743 Cortex M7 core with DSP and DP-FPU, max frequency 480 MHz |

| IO Processor | No |

| RAM | 1MB RAM |

| Flash | 2 MB |

| FRAM module | 256kb - for parameters only |

| Accelerometers / Gyros / Mags | 3x Accelerometers / 3x Gyros / 1x Mag |

| Sensors | Invensense/TDK ICM-20602 (6DOF) Invensense/TDK ICM-20948 (9DoF) |

| Sensors – Dampened | Bosch BMI088 (6DOF) (internally vibration dampened) |

| Internal Magnetometer | AK09916 embedded in ICM-20948 |

| Barometer | Infineon DPS368 barometer (Very smooth and NO light sensitivity, high-humidity environments) |

| Interfaces and Protocols | 6x UART (serial ports) [3x with HW flow control]. 1x SBUS/PPM sum input signal 8x PWM outputs (all D-Shot capable) 1x RSSI (PWM or voltage) input 3x I2C 1x SPI (optional, instead of 1 UART) 2x CAN 1x SWD (TC2030 Connector) Supported RC input protocols: Spektrum DSM / DSM2 / DSM-X® Satellite compatible input and binding. Futaba S.BUS® & S.BUS2® compatible input. FrSky Telemetry port output. Graupner SUMD. Yuneec ST24. |

| Mating Connectors | CLM-118-02 CLM-120-02 |

| Pin Headers | Yes |

| Conformal Coating | Optional |

| Extended Testing and Burn In | Yes |

| Custom Carrier Board Support | Yes |

| Notify LED | Yes (RGB) |

| Dimensions | Width: 20mm (0.79″) Length: 35mm (1.38″) Height: 6.8mm (0.28") |

| Weight | 3.5g (0.12oz) 3.8g (0.13oz) w/ micro SD Card |

| Mounting Holes | No |

| Case | Optional aluminum thermal and mechanical protection |

| Typical Platforms | - Multirotor - Rover - Fixed-Wing - Boats - Submarines - VTOL - Automatic Tractors - Others |

| Electrical | 5.25V @400mA minimum, 2A recommended, 1A minimum |

Purchase Auto Pilot Purchase Case

Warning

Be cautious when removing the OEM from ANY carrier board, ESD safe plastic tweezers were provided for this task. This is true especially for M10112 boards where aggressive weight saving measures were taken.

About IO coprocessors and AUX Pins

Historically, microcontrollers mounted on Autopilots didn't have enough resources to handle the requirements that industry was demanding. Usually, the features needed to keep up with the trends, pushed manufacturers to add IO coprocessors to increase the number of available timers to generate and decode PWM signals and additional IO Pins. The coprocessor in these hardware architectures is usually connected via a single serial port, reducing the amount of data available in time and introducing more points of failure. This arrangement pushed the pins to be divided by MAIN and AUX Pins, where MAIN were the pins connected to the MCU and AUX to IO coprocessors. However, later generations of hardware have increased IO pin density, timers and reduced size factor, among other enhancements. Additionally, a special benefit also stands out for our design principles, and it is the higher amount and more sophisticated DMAs that work really well with peripherals, transferring high amounts of data and decreasing CPU usage. Besides, we are transitioning from a single MCU architecture to more distributed systems thanks to DroneCAN and Ethernet connectivity (coming soon). In practical terms, you can consider every available PWM pin in your board as you would for an AUX pin.

Design changelog

The changelog for this product can be found at this link.

Quick start

Install the board on its carrier and connect via USB to start configuring parameters and connecting peripherals.

Danger

When mounting the Control Zero H7 OEM into its mating connectors on any carrier board ensure connectors are properly matched and aligned and that no power is applied to the board. If power is applied when the board is not connected properly you will cause irreversible damage to the board.

The board comes with Ardupilot stable pre-installed from factory. However, the bootloader provides an interoperation layer with PX4 as well, so QGC will be able to detect it and load firmware adequately. There is no need to change the bootloader if you want to flash PX4.

We encourage all customers to run the latest indicated version available in the Compatibility table below for your preferred flight stack.

Firmware and status

The 3DR Control Zero OEM is compatible with the following firmware:

ArduPilot

Bootloader now available at TELEM1 port as well.

PX4

| Compatibility | Ardupilot | PX4 |

|---|---|---|

| Stable | Stable |

| latest | main |

Note: Rev E(D) and rev G are both in active production to provide support for customers running custom firmware.

Some additional resources:

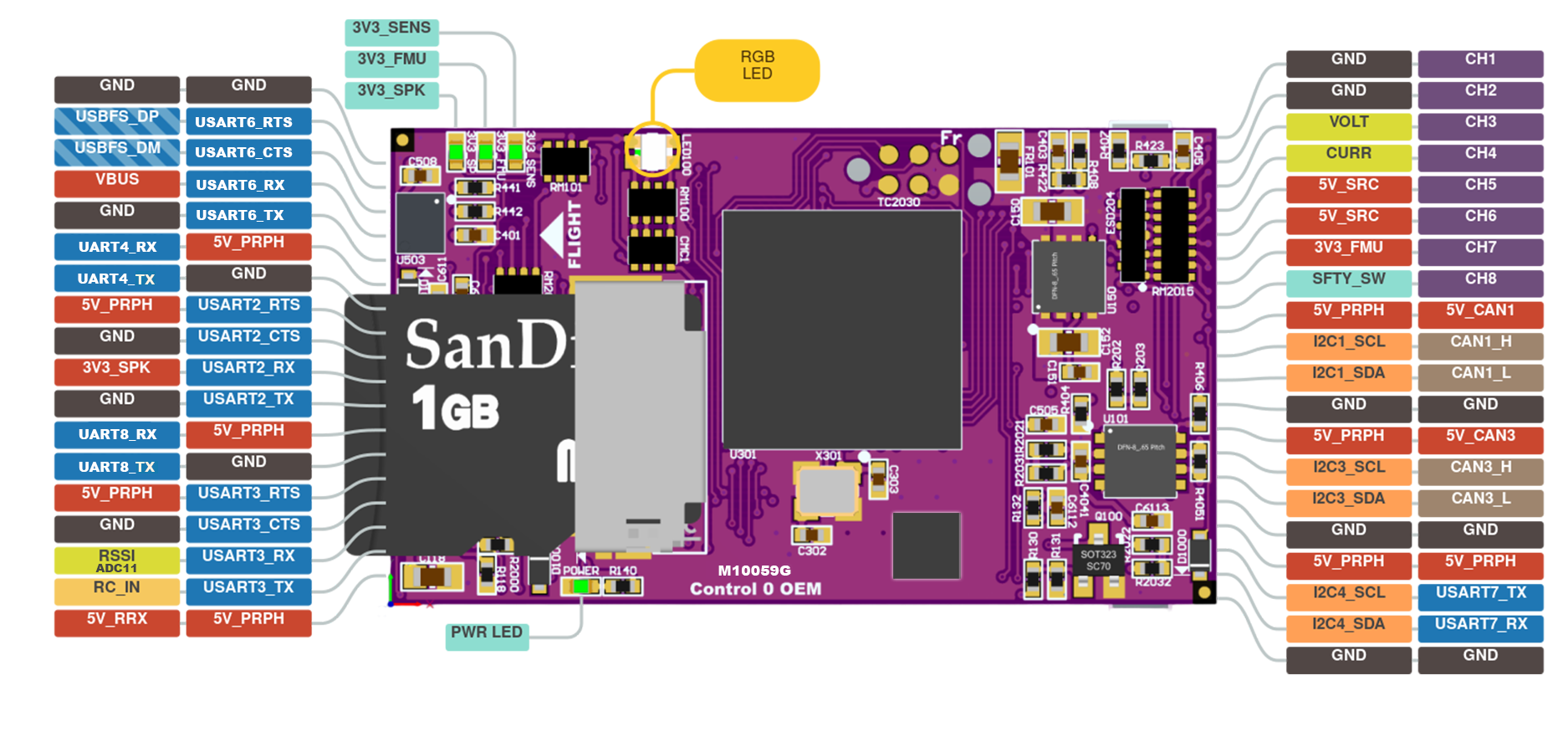

Graphical pinout

The serial ports default assignment is as follows:

| Serial | Port name | AP Serial | Flow Control |

|---|---|---|---|

| USART2 | TELEM1 | SERIAL 1 | YES |

| USART3 | TELEM2 | SERIAL 2 | YES |

| USART4 | GPS | SERIAL 3 | NO |

| UART8 | GPS2 | SERIAL 4 | NO |

| UART7 | Additional UART | SERIAL 5 | NO |

| USART6 | Additional UART | SERIAL 6 | YES |

Custom builds may be needed if you want to change default functionality for UART/SPI 6, this depends on the selected flight stack firmware.

If you have further questions contact us.

Power considerations

The board is intended to be powered either from the power 'brick' labeled as 5V_SRC in the above diagram or the VBUS pin or both; 5.25V is recommended due to protection diodes, this way you'll avoid getting low voltage warnings from the ground station software. The CZ OEM is able to provide up to 500 mA (fused) to the 5V_PRPH power domain, exceeding this current will damage the board.

%%{init: {'theme':'dark'}}%%

flowchart LR

in1>5V_SRC] -->|1.75A fuse| n1(OR-diode)

in2>VBUS] --> n1

n1 --> vin{"`5V_IN

(PWR_LED)`"}

vin --> |1A LDO| int1([3V3_FMU])

vin --> |Schottky| out1[5V_RRX]

vin --> |"SPEKTRUM_POWER [PE4] 250 mA"| out3[3V3_SPK]

vin --> |Fused ~500mA| out2[3V3_SPK]

subgraph Inputs

in1

in2

end

subgraph Power outputs

out2

out1

out3

end