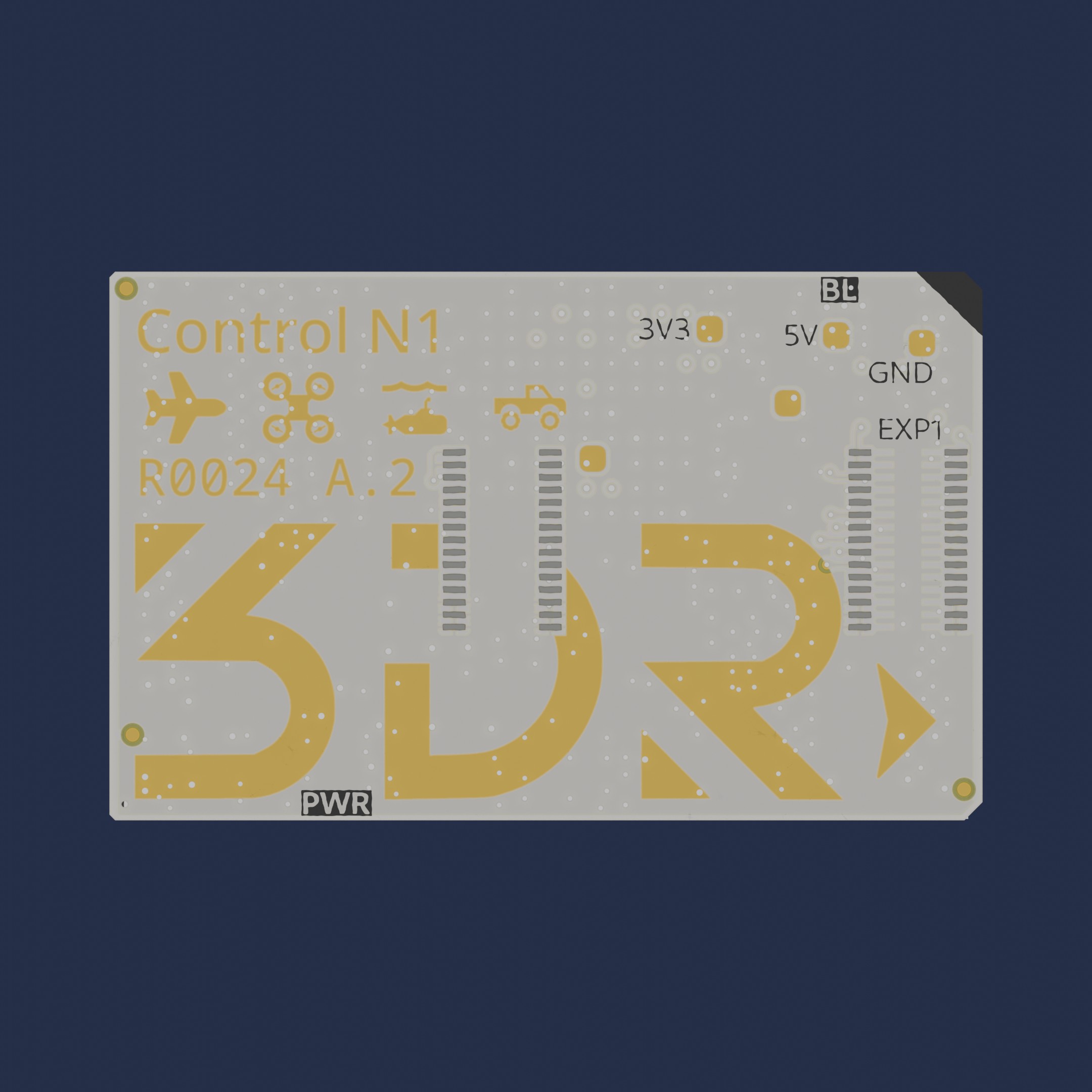

Control N1 - R0024

Meet Control N1. Our smallest, lightest, and most versatile AutoPilot Module. At just 17.6mm × 28mm and 2.3g, this tiny powerhouse brings full ArduPilot and PX4 flight control to even the most space and weight constrained designs yet remains a cost effective solution.

Key Features

- Ultra-Compact & Feather-Light - Barely bigger than a stamp — 17.6×28mm and under 2.7g -, the CN1 integrates into small UAVs, ROVs, UUVs, and custom robotics platforms without compromise.

- High-Performance Core - Powered by an STM32H7 MCU, it delivers the processing horsepower needed for stabilized flight, advanced mission planning, and real-time sensor fusion—and leaves over 50% of its compute capacity reserved for future enhancements and custom applications.

- Single-Sided design - We've engineered the entire autopilot onto a single-sided PCB—minimizing board area and complexity for effortless manufacturing, faster turnarounds, and lower cost. Simplicity increases robustness ("the best part is no part"), reducing potential failure points and boosting reliability.

- Flexible and Future-Proof Board-to-Board Interface - Designed with the future in mind, our board footprint –similar to a Raspberry Pi CM5 connector type – exposes spare signal pins so you can create future custom controller boards, not just carrier boards—in other words, you can reuse all your existing carrier/main boards and progressively upgrade them at your own pace.

- Real-World Sensor Selection - We didn't pick components on paper alone. Through extensive in-field testing and experience, we hand-select only the very best sensors. Expect performance so ahead of the curve that competitors will continue to follow our lead.

- Affordable, US-Made Excellence - Proudly designed and manufactured in the USA, the CN1 undercuts bulkier, heavier-and more expensive- competitors while delivering premium flight-control features—and we don‘t cut corners where people can't see, we only use reputable passive and active component brands like Murata, STMicro, Texas Instruments, NXP, and more.

- Open-Source Ecosystem - As our core tradition, we offer full compatibility with ArduPilot and PX4 communities means instant access to mature firmware, mission-planning tools, and global support.

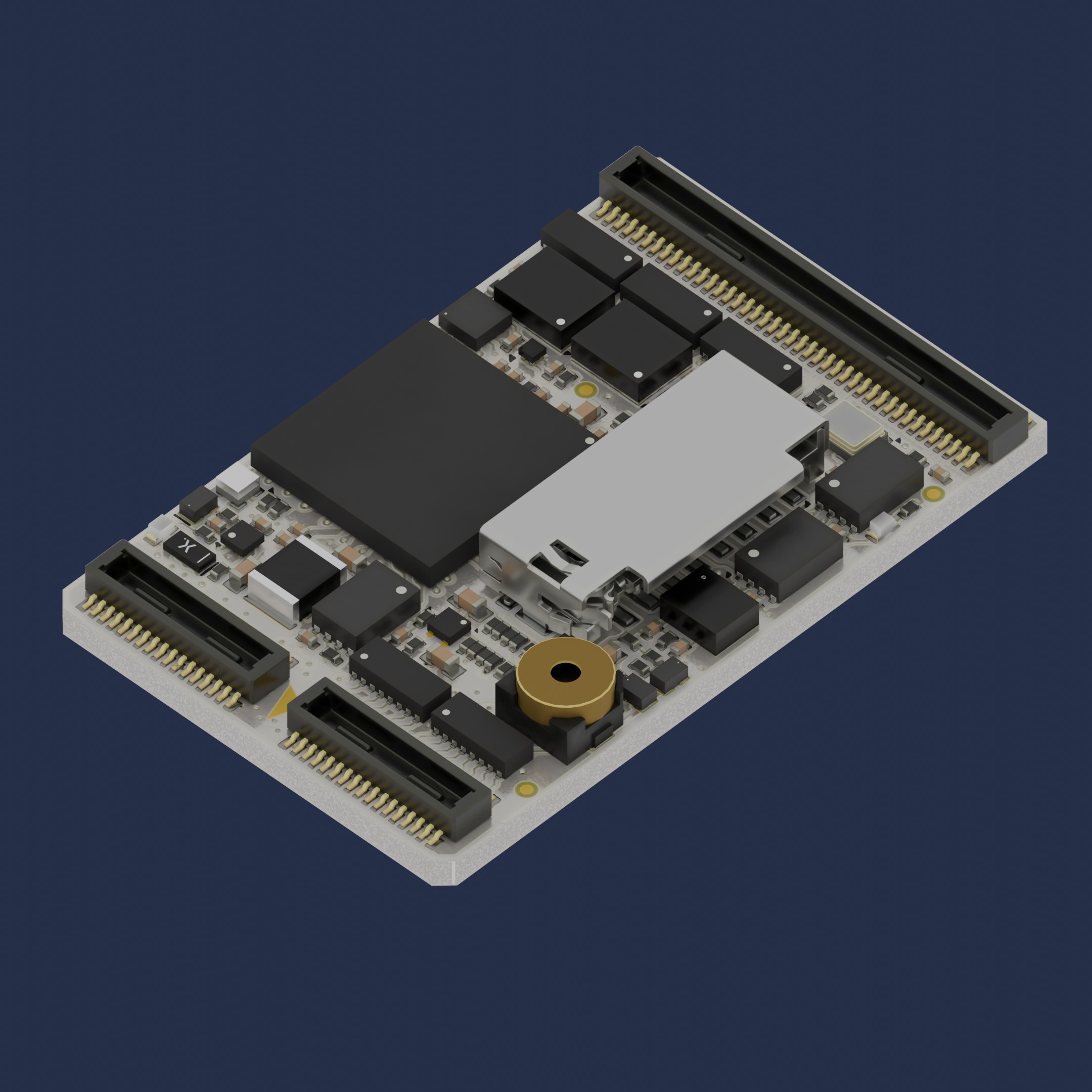

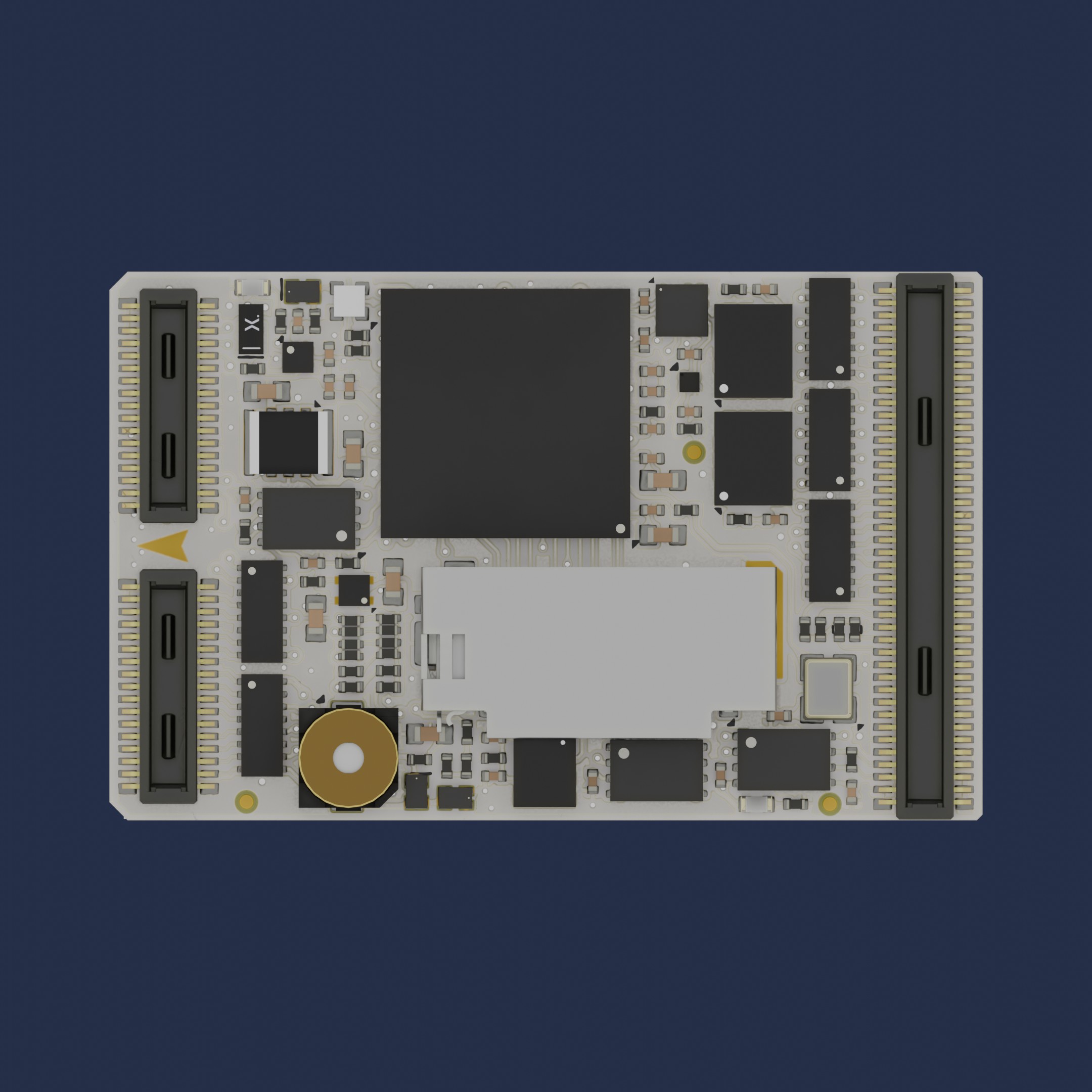

3D View

Specifications

General

| Autopilot | Control N1 |

|---|---|

| Main processor | STMicro® STM32H743 Arm® Cortex®-M7 core, double-precision FPU up to 480 MHz fCPU |

| L1 cache | 16 Kbytes of I-cache 16 Kbytes of D-cache |

| RAM | 1 MB |

| Flash | 2 MB |

| Memory | 8 MB |

| Sensors | 2x Accel/Gyro 1x Magnetometer 1x Barometer |

| Inertial Sensor | 2x InvenSense IIM-42653 (6DoF) |

| Magnetometer | Asahi Kasei Micro AK09940A |

| Barometer | Infineon DPS368 barometer |

| Interfaces and ports | # of instances and capabilities |

|---|---|

| Motor outputs | 12x PWM, DShot (BIDIR), GPIO |

| Serial | 7x total 3 full-duplex with flow control 4 full-duplex |

| CAN | 2x FD-CAN (up to 8 Mbps) |

| I2C | 2x Fast mode (up to 400kHz) |

| SPI | 1x Up to 40 MHz CLK speed One dedicated CS line, GPIOs available as extra CS |

| GPIO | 4x Push-Pull direct from MCU |

| USB | 1x USB Full Speed STM32H7 MCU native port |

| SDIO/SDMMC | 1x SDMMC interface Shared with socket |

| Addressable LED | 1x Pin from onboard LED (chainable) |

| Debug | 1x Serial wire debug (SWD) lines available BOOT0 pin available |

Mechanical

| Parameter | Value |

|---|---|

| Horizontal dimensions | 28 mm x 17.6mm 1.102” x 0.693” |

| Height | 3.7 mm 0.145” |

| Weight | 2.32 g 0.082 oz |

| Connectors | Amphenol® BergStak® series |

| Mated assembly height | 4.5 mm 0.177” |

Electrical

| Parameter | Value or range |

|---|---|

| Input voltage (VDD) | 4.8 V - 6.0 V |

| Typical current draw | ~230 mA |

| Operating temperature | -20 - 75 C [TBC] |

| Storage temperature | -40 - 85 C |

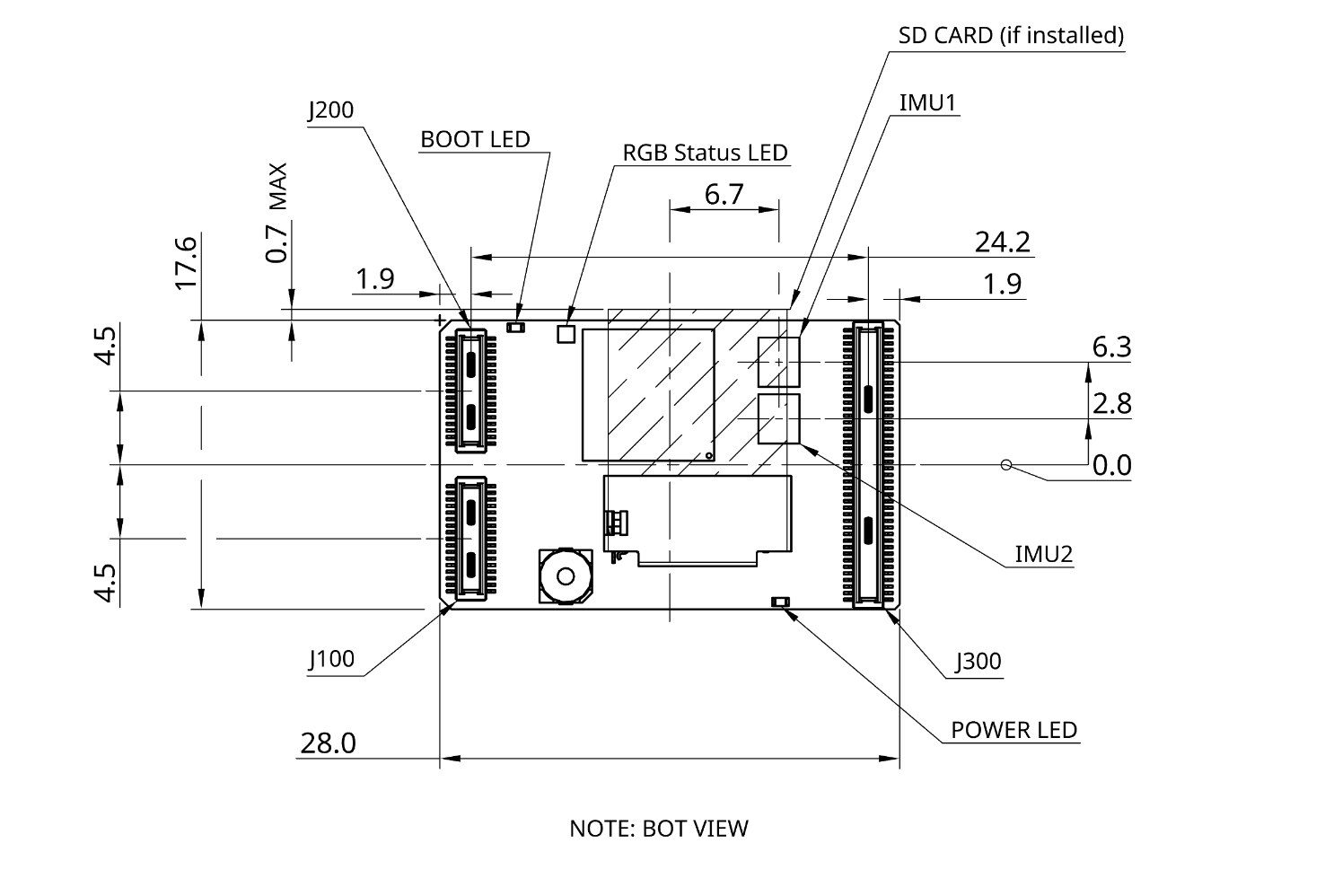

2D drawing

A description of the board's connectors placement is provided in the following drawing, a PDF version is available in the downloads section.

Pinout

Control N1 uses a new socket specification which comprises 140 pins split into 3 DF40 type connectors (Hirose). We are commited to supporting this footprint in future releases.

| Reference | Pin count | Part number | Alternative PN |

|---|---|---|---|

| J100 | 30 | DF40HC(3.5)-30DS-0.4V(51) | 10164227-0305A1RLF |

| J200 | 30 | DF40HC(3.5)-30DS-0.4V(51) | 10164227-0305A1RLF |

| J300 | 80 | DF40HC(3.5)-80DS-0.4V(51) | 10164227-0805A1RLF* |

A note on mating connector height

The 3.5mm height connector is used for the default configuration, however depending on the end user needs, a different connector height may be used. It is possible to order the board with no buzzer and no SD card slot installed, allowing for a more compact footprint.

A comprehensive pinout table is available below. The table follows the physical layout of the connectors so there are two pins per row. If you are using KiCad to capture your design, you can download the template project from our downloads section.

Pinout tool

J100

| Group | Name | Pin | Pin | Name | Group |

|---|---|---|---|---|---|

| POWER | GND | 1 | 2 | USART2_TX | SG1 |

| USB | USB_DM | 3 | 4 | USART2_RX | SG1 |

| USB | USB_DP | 5 | 6 | USART2_CTS | SG1 |

| POWER | GND | 7 | 8 | USART2_RTS | SG1 |

| SDMMC | SD_DET | 9 | 10 | GND | POWER |

| SDMMC | SDIO_D1 | 11 | 12 | UART4_TX | SG2 |

| SDMMC | SDIO_D0 | 13 | 14 | UART4_RX | SG2 |

| SDMMC | SDIO_CK | 15 | 16 | UART4_CTS | SG2 |

| POWER | GND | 17 | 18 | UART4_RTS | SG2 |

| SDMMC | SDIO_CMD | 19 | 20 | GND | POWER |

| SDMMC | SDIO_D3 | 21 | 22 | USART3_TX | SG4 |

| SDMMC | SDIO_D2 | 23 | 24 | USART3_RX | SG4 |

| POWER | GND | 25 | 26 | GND | POWER |

| MISC | ALARM | 27 | 28 | USART1_TX | SG5 |

| POWER | GND | 29 | 30 | USART1_RX | SG5 |

J200

| Group | Name | Pin | Pin | Name | Group |

|---|---|---|---|---|---|

| SWD | SWCLK | 1 | 2 | USART6_TX | SG6 |

| SWD | SWDIO | 3 | 4 | USART6_RX | SG6 |

| POWER | GND | 5 | 6 | RESERVED | - |

| - | AP_nRST | 7 | 8 | RESERVED | - |

| - | BOOT0 | 9 | 10 | GND | POWER |

| POWER | GND | 11 | 12 | RESERVED | - |

| FDCAN | FDCAN1_5V | 13 | 14 | RESERVED | - |

| FDCAN | FDCAN1_H | 15 | 16 | GND | POWER |

| FDCAN | FDCAN1_L | 17 | 18 | ADDR_LED | MISC |

| POWER | GND | 19 | 20 | RESERVED | - |

| - | BRD_EN | 21 | 22 | SPI_SCK | SPI |

| POWER | 5V_PWRIN1 | 23 | 24 | SPI_SDI | SPI |

| POWER | 5V_PWRIN1 | 25 | 26 | SPI_SDO | SPI |

| POWER | GND | 27 | 28 | SPI_nCS | SPI |

| POWER | GND | 29 | 30 | RESERVED | - |

J300

| Group | Name | Pin | Pin | Name | Group |

|---|---|---|---|---|---|

| POWER | GND | 1 | 2 | GND | POWER |

| FDCAN | FDCAN2_L | 3 | 4 | GND | POWER |

| FDCAN | FDCAN2_H | 5 | 6 | 5V_PWRIN2 | POWER |

| FDCAN | FDCAN2_5V | 7 | 8 | 5V_PWRIN2 | POWER |

| POWER | GND | 9 | 10 | 3V3_AP | POWER |

| - | RESERVED | 11 | 12 | RESERVED | - |

| - | RESERVED | 13 | 14 | RESERVED | - |

| POWER | GND | 15 | 16 | RESERVED | - |

| - | RESERVED | 17 | 18 | RESERVED | - |

| - | RESERVED | 19 | 20 | GND | POWER |

| POWER | GND | 21 | 22 | RESERVED | - |

| I2C | I2C2_SDA | 23 | 24 | RESERVED | - |

| I2C | I2C2_SCL | 25 | 26 | GND | - |

| POWER | GND | 27 | 28 | ADC1_INP10 | ADC |

| I2C | I2C1_SDA | 29 | 30 | ADC1_INP4 | ADC |

| I2C | I2C1_SCL | 31 | 32 | GND | POWER |

| POWER | GND | 33 | 34 | RESERVED | - |

| SG7 | UART5_RX | 35 | 36 | RESERVED | - |

| SG7 | UART5_TX | 37 | 38 | RESERVED | - |

| POWER | GND | 39 | 40 | RESERVED | - |

| SG3 | UART7_RTS | 41 | 42 | GND | POWER |

| SG3 | UART7_CTS | 43 | 44 | GP4 | GPIO |

| SG3 | UART7_RX | 45 | 46 | GP3 | GPIO |

| SG3 | UART7_TX | 47 | 48 | GP2 | GPIO |

| - | RESERVED | 49 | 50 | GP1 | GPIO |

| - | RESERVED | 51 | 52 | GND | POWER |

| POWER | GND | 53 | 54 | CH12 | MOT/GPIO |

| - | RESERVED | 55 | 56 | CH11 | MOT/GPIO |

| POWER | GND | 57 | 58 | CH10 | MOT/GPIO |

| - | RESERVED | 59 | 60 | CH9 | MOT/GPIO |

| - | RESERVED | 61 | 62 | GND | POWER |

| - | RESERVED | 63 | 64 | CH8 | MOT/GPIO |

| POWER | GND | 65 | 66 | CH7 | MOT/GPIO |

| - | RESERVED | 67 | 68 | CH6 | MOT/GPIO |

| POWER | GND | 69 | 70 | CH5 | MOT/GPIO |

| - | RESERVED | 71 | 72 | GND | POWER |

| - | RESERVED | 73 | 74 | CH4 | MOT/GPIO |

| POWER | GND | 75 | 76 | CH3 | MOT/GPIO |

| - | RESERVED | 77 | 78 | CH2 | MOT/GPIO |

| - | RESERVED | 79 | 80 | CH1 | MOT/GPIO |

Serial ports

For ease of use, the serial ports are grouped into SG1, SG2, SG3, SG4, SG5, SG6, and SG7. These are arbitrary choices, but match the template project naming and firmware definitions.

| Serial group | Location | STM32 Peripheral | AP Serial param | Flow Control | Default AP function |

|---|---|---|---|---|---|

| SG1 | J100 | USART2 | SERIAL1\_\* | YES | TELEM1 |

| SG2 | J100 | UART4 | SERIAL2\_\* | YES | TELEM2 |

| SG3 | J300 | UART7 | SERIAL6\_\* | YES | N/A (USER) |

| SG4 | J100 | USART3 | SERIAL4\_\* | NO | GPS2 |

| SG5 | J100 | USART1 | SERIAL7\_\* | NO | N/A (USER) |

| SG6 | J200 | USART6 | SERIAL5\_\* | NO | ELRS RX (USER) |

| SG7 | J300 | UART8 | SERIAL3\_\* | NO | GPS |

Important note

The serial ports are configured to use the default AP function, given by the SERIALx_PROTOCOL parameter. However, you can change the function, as the definition is arbitrary. Per Ardupilot's wiki: \"Any supported protocol/peripheral can be used by any port by changing its SERIALx_PROTOCOL parameter.\"

What is "Default AP function?"

Ardupilot assigns a default function to the first 5 serial ports according to the following table. For more info, see Ardupilot's wiki here.

Quick start

Install the board on its carrier and connect via USB to start configuring parameters and connecting peripherals.

The board comes with Ardupilot Copter dev or stable pre-installed from factory. However, the bootloader provides interoperability with PX4 as well, so QGC will be able to detect it and load firmware adequately. There is no need to change the bootloader if you want to flash PX4. For more information, see our firmware update guide.

We encourage all customers to run the latest indicated version available in the Compatibility table below for your preferred flight stack.

Supported firmware

Warning

Our firmware is under active development, which means you can expect ongoing improvement and refinements. We’re committed to keeping you updated along the way.

The 3DR Control N1 is compatible with the following firmware:

ArduPilot

Pending.

PX4

Pending.

Some additional resources:

About IO coprocessors and AUX Pins

Historically, microcontrollers mounted on Autopilots didn't have enough resources to handle the requirements that industry was demanding. Usually, the features needed to keep up with the trends, pushed manufacturers to add IO coprocessors to increase the number of available timers to generate and decode PWM signals and additional IO Pins. The coprocessor in these hardware architectures is usually connected via a single serial port, reducing the amount of data available in time and introducing points of failure. This arrangement pushed the pins to be divided by MAIN and AUX Pins, where MAIN were the pins connected to the MCU and AUX to IO coprocessors. However, later generations of hardware have increased IO pin density considerably, as well as increased the number of timers, among other enhancements. A special benefit stands out for our design principles, and it is the higher amount and more sophisticated DMAs that work really well with peripherals, transferring high amounts of data and decreasing CPU usage. Besides, we are transitioning from a single MCU architecture to more distributed systems thanks to DroneCAN and Ethernet connectivity (coming soon). In practical terms, you can consider every available PWM pin in your board as you would for an AUX pin.

Available ordering options

Control N1 Product Tiers

| Tier | Personal-Tinkerer | Industrial/Business | Partner/OEM |

|---|---|---|---|

| Support | Community | 1- or 2-day ticket response | All in Business Custom or no logo Custom sensors Custom signed BL |

| Bootloader | Open | Signed (or open) | |

| Firmware | Upstream flight stacks - PX4 and Ardupilot | Tested binaries, 3DR distributed | |

| Calibration | From IMU vendor | Factory calibrated across all temperature range after assembly Test reports Temp cycling | |

| Sensors | Standard | Upgraded | |

| Price | $99 | $149 to $549 | Contact us |

| Custom options | Description |

|---|---|

| Conformal Coating | Optional |

| Thermal calibration | Optional |

| Ultra-low profile (No SD card socket and no buzzer) | MOQ applies |